How much does laser cutting cost?

How much does laser cutting cost?

No matter the size of the undertaking, from an individual’s passion project to a multi-million pound fabrication contract, the cost of laser-cut components is always important to you, the customer. There’s never an easy, straightforward answer to give clients when it comes to laser cutting pricing – and there are good reasons for that. There are a series of factors that professional, reliable firms need to consider when they prepare a quote, including:

- Materials

- Time

- Overheads

- Labour

- Delivery

How the cost of laser cutting is calculated

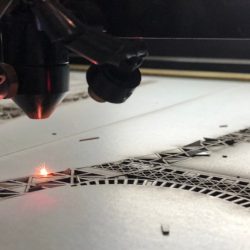

When you ask for a quote from a laser cutting firm, they will use the drawings and information you’ve had created for the specific parts you require and enter it into Computer-Aided Design (CAD) software to calculate the processing time, the weight and the materials needed and come up with an initial cost.

Then they will ‘nest’ the parts onto different sheets of metal to achieve the optimal use of material. Once all the relevant information is on file in the system, a good fabrication firm will be able to change the quantity, thickness or material in your order to recalculate the quote so you can consider a variety of options.

Material costs

The cost of materials is the factor that’s most prone to fluctuate, as the price of steel and other metals varies daily, depending on availability and demand. Yorkshire Laser work hard to establish excellent relationships with a range of suppliers, so when we get a keen price we’re able share the savings with you. Order volume can also affect the cost of materials – the price of a specific single sheet for a small piece of work is significantly higher than ordering in bulk, which also must be taken into consideration. Higher volumes lead to lower costs per unit overall.

How long it takes

The time any job takes depends on the type of material its grade and thickness. Denser metals and thicker sheets will take more time to cut than some thinner, less dense materials. YLF use the latest software, technology and laser cutting machines to reduce running times and keep the price per part as low as possible.

Labour

This is fairly obvious, but your order will be worked on by potentially dozens of people in a wide range of jobs before it is handed over to you – and they all need to get paid. From the office staff who handle your initial order enquiry through to the warehouse team, there are also machine specialists who operate the laser cutter, CAD engineers, production managers, quality control experts and dispatch teams who make sure everything is ready for delivery or collection.

Laser cutting machine running costs

It sounds pretty obvious, but it’s still worth explaining – running and maintaining state-of-the-art equipment, workshops and offices all cost money. Electricity is a major expense and laser cutting can be a power-hungry business, which needs to be taken into account when we work out the best price for your project. Cutting some of the thicker, denser sheets means the machine uses more energy as well as taking more time to cut.

Yorkshire Laser and Fabrication pride ourselves on providing all customers with exceptional quality, service and the best value. Give us a call on 01924 220236, email info@yorkshirelaser.co.uk or click here to get in touch.