Sheet Metal Fabrication in the Automotive Industry

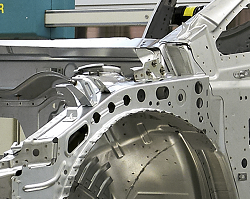

Yorkshire Laser understands the essential role that sheet metal fabrication plays within the automotive industry – it is used for the production of thousands of individual vehicle parts that are engineered and fitted together to form the cohesive whole of a single automobile.

We have extensive experience in providing a range of automotive parts to our clientele base and consider no request too large or too small.

Some of our Sheet Metal Fabrication Projects for the Automotive Industry

We have worked with large-scale vehicle manufacturers to produce high-production runs of specific pieces of metal; we have provided replacement parts to mechanics located within the local and wider area; and we have worked with car enthusiasts across Europe who were in need of bespoke, reproduction parts in order to restore vintage models.

Technology and Sheet Metal Fabrication

Our knowledge, experience and problem solving has served a range of different customers. We have continually invested heavily over the past 15 years in sourcing the necessary technology and equipment needed so as to enable us to broaden the services that we offer.

In order to offer our customers a diverse range of sheet metal fabrication options for automobiles, our premises is stocked full of state-of-the-art machinery and software.

CAM/CAM

We extensively use Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) technology. Our professional and experienced CAD engineers are able to design any part virtually on a computer screen before the physical manufacturing process begins. This enables us to be exact with our measurements and the shaping of the piece of metal, regardless of how complex its design may be.

Sheet Metal Enclosures

Sheet metal enclosures within automobiles can be used to protect electronics from wear and tear and these enclosures tend be made up of several pieces of metal, shaped and fitted together. As such, by first producing a design on-screen, we are able to see how each individual part functions and fits into the enclosure as a whole.

This part of the processes is known as Computer Aided Quality Assurance (CAQA) and it enables us to iron out any potential problems with the overall design before production begins. This element of our design process ensures the safety of the part and is more cost-efficient in the long-term.

Sheet Metal Fabrication Using Computer Aided Manufacturing

Our use of Computer Aided Manufacturing in metal forming encompasses two key means of production, namely Computer Numerically Controlled (CNC) folding and Computer Numerically Controlled (CNC) punching.

CNC Folding

CNC folding is, essentially, the shaping of metal and it is important that this process is exact. A side panel for a car can contain several curves and cutaways. If too much force is applied to a piece of metal when it is being worked upon then it can break, whereas too little force can result in the curve not being exact.

Computer Numerically Controlled folding thus allows us to apply the exact amount of force to the exact point of the metal, meaning that the end product comes out perfectly formed and shaped to your specific request.

CNC Punching

CNC punching is especially important in sheet metal fabrication and the production of sheet metal enclosures for automobiles. A standard car contains approximately 30,000 parts, all of which have to be either welded or fixed together with good old-fashioned nuts and bolts.

Our use of CNC punching allows us unparalleled precision in the punching of holes into sheet metal. With both CNC folding and punching, the necessary designs are again first rendered and tested virtually, before the manufacturing process begins.

Safety is of paramount importance in the production of vehicle parts and CNC punching produces exact holes designed to fit nuts, bolts and washers perfectly and for the duration of the road life of a vehicle.

Our Ethos

We have served thousands of happy customers over the years. Whether you require a side panel, a new bonnet, a sheet metal enclosure for the internal mechanics of a vehicle or a custom-built part for your restoration project – our team can offer you the most contemporary and safest means of design and production.

Our design, manufacturing and testing processes are exact and rigorous. We pride ourselves on meeting the specific needs of our customers, regardless of how large or small their particular request may be.

By creating preliminary designs on our software programmes, we ensure that your finished product is safe, perfectly formed and cost-effective.