What is sheet metal fabrication used for?

It’s one of those phrases that we’ve all heard. We’ve seen it emblazoned on vans and on workshop signs – but what is sheet metal fabrication actually used for?

Here, we’ll try to explain exactly what it means, and how and why it’s used across a wide range of industries and sectors.

The basics…

Put simply, sheet metal fabrication is the process of creating metal structures or parts from raw materials such as stainless steel.

Often, sheets of stainless steel or other metals are processed and assembled to create a larger product.

Techniques such as laser cutting, bending, punching and welding are all used in the sheet metal fabrication process to create a range of products of varying shapes and sizes.

Completed sheet metal products can range from simple open boxes to electro-mechanical assemblies that incorporate hundreds of components.

Precision-machined metal parts are a vital component of many products. Many businesses need large quantities of metal components for use in a wide range of sectors, from cars and aviation to medical equipment and lighting.

Sheet metal fabrication techniques

Of course each job is different, but most sheet metal fabrication projects consist of the following key phases:

Design

Using computer-aided design software (CAD), firms like Yorkshire Laser and Fabrication work with the client to create detailed drawings and schematics of how the product should look, and how it should be manufactured.

The team uses the CAD software to work out dimensions, which materials to use, fasteners, revision levels and anything else of relevance to create a high-specification final product.

Programming

Once the designs have been approved and finalised, they are digitally transferred to the machinery that creates the products. Parts are drawn in 2D form on sheet metal such as stainless steel, ensuring that material utilisation is maximised.

Cutting

As one of the most accurate ways of cutting sheet metal, laser cutting users laser machines to follow the programmed design and with precision and speed to create the required parts.

What’s more, laser cutting machines don’t need human supervision once they have been given the exact measurements.

Punching

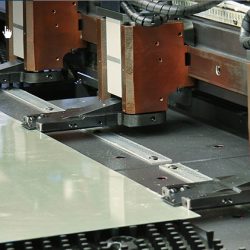

A lot of sheet metal components need forms or perforations such as countersinks, ribs or louvres.

To achieve this, a CNC (computer numerical control) punching machine uses tools to ‘hit’ the sheet metal and either shape or perforate it in specific ways.

Folding

Sometimes known in the sheet metal fabrication industry as CNC bending, the CNC folding process uses powerful machines that are capable of bending sheet metal with ease.

Sheet metal like stainless steel is bent into shape by a press brake.

The press brake’s upper tool, the punch, pushes the metal against the bottom tool, called the die.

The punch and die’s movement is controlled by the press brake, with the force coming from hydraulic rams and electric motors.

Most electrical boxes, brackets and enclosures are formed through this method.

Welding

A range of welding techniques are used in sheet metal fabrication including MAG welding, TAG welding, spot welding, projection welding and robotic welding.

Yorkshire Laser has decades of experience in sheet metal fabrication. We’re industry experts in areas such as laser cutting; mild steel fabrication; stainless steel fabrication; aluminium sheet fabrication and galvanised or Zintec materials.

Our sector expertise includes:

- Medical

- Architectural

- Fencing

- Lighting

- Sheet metal enclosures

- Shop fittings

- Furniture

- Conveyor parts

We’ll work with you to ensure that the sheet metal fabrication you require is made to suit your exact specifications, saving you time and money.

If you would like to discuss a quote or speak to our experts about how we can get involved with your sheet metal fabrication project, call us on 01924 220236 or email info@yorkshirelaser.co.uk.

The Yorkshire Laser sheet metal fabrication team will work alongside you – find out more about our sheet metal services here.